What is the Plan-Buy-Pay Process?

by Yoann Bierling

What is the Plan-Buy-Pay Process?

What is the Plan-Buy-Pay Process?

The Plan-Buy-Pay process, which is the basic concept behind the Ariba business network, is the idea that the whole procurement process is interconnected, with the possibility to plan for needed goods in a company, that will be procured either from an external producer, or internally from another warehouse, and that these requirements which have been planned will be effectively ordered through a buying process.

Once the purchase order has been processed, and the goods have been delivered, the payment can take place, thus leading the company to acquiring what is effectively needed for the production, sales, or office purposes.

See in detail below how these concepts are working together and support the Ariba business network.

Figure 1: Plan – Buy – Pay process

Planning Process

The planning process starts with demand determination: what is needed by the company, which is expressed in terms of demands. The company’s internal employees and streams can express requests of goods or services that are needed to execute their jobs.

Once they have analysed their needs and planned their demands, it is necessary to discover possible sources of procurement that could potentially fulfil these requests. The source determination process will do that, by discovering possible new suppliers, registering them in the list of approved providers, after what some quality checks can be ran, in the form of a request for quotation, also called RfQ.

Each of the suppliers are then contacted, asked to send a quote, and negotiations can start for the supplier selection. The one with the best offer can be chosen, which might not only be based on price. The quality can also be taken in consideration, as well as other factors, such as delivery time, distance, or other predefined criteria.

Selecting the final supplier will result in the creation of a contract, which could be a simple Purchase Order, or can be accompanied by a more complex contract including discounts per volume, or any kind of clause, leading to the start of the buying process.

Figure 2: Planning part of the Plan - Buy - Pay process

Buying Process

Once a purchase order has been created and sent to a supplier, with which a more specific contract may or may not exist, the buying process starts.

Sending the purchase order to a supplier is a legally binding action, as we make the promise that we will pay the goods or service that we planned to get from a specific provider from which we will buy them.

The buying process contains both the purchase order processing, and the goods receipt. Purchase order processing means creating the purchase order and sending it to the supplier, and the process is completed once the goods or services have been delivered and checked, in terms of quality and quantity.

In the middle of these two actions, the payment process starts – once the goods have left the supplier’s warehouse, in accordance to the purchase order that has a been sent, a payment will have to be triggered later on, after the goods will have been checked and validated.

Figure 3: Operational buying part of the Plan - Buy - Pay process

Payment Process

Payment process starts after the purchase order has been sent to the provider, and the goods have left his warehouse.

The order can be monitored, and a payment will have to happen once the order will have been delivered.

However, compensation might not be equal to the purchase order. It depends entirely on the invoice verification, during which the purchase order will be checked against the goods receipt.

The goods that are validated in terms of quality and that have been request in the purchase order will have to be paid, while goods that have not passed the quality checks will require further processing and discussions with the provider, depends on the contract that has been agreed on during the planning part.

Credit notes can be issues, depending on the state of the delivery. Payment will be processed once the invoice has been settled.

Figure 4: Operational paying part of the Plan - Buy - Pay process

Ariba and the Plan-Buy-Pay Process

The Plan-Buy-Pay process has to be considered as a whole, as none of the planning part and operational parts can be done alone.

The company wants to pay for the order that have been planned to be bought. Internally, it leads to several teams working together, and ensuring that the whole operational procurement process is correctly managed:

- The production planning team defines a list a of needed raw materials for production,

- The procurement team finds possible suppliers, and select the best one for the purchase order processing,

- The legal team reviews the contracts that already exists or that are newly negotiated,

- The warehousing team tracks the goods arrival, and, once they arrive, check their quality, and stores them for future use by the production team,

- The finance team pays the supplier for the order delivery and manages eventual issues regarding contract agreement and delivered quality.

This whole Plan – Buy – Pay process is integrated in the SAP Ariba business network and allows companies to access a whole network of suppliers, with which all of these operations can be managed.

It is not necessary to be an active SAP user to access the Ariba network, as Ariba has its own way of managing product catalogues and relationship between order and supply.

Video lesson: SAP Ariba Supply Chain Collaboration Overview

Introduction to SAP Ariba Course

Learn more about the SAP Ariba processes and see how the Plan – Buy – Pay process is integrated, by following our online course Introduction to SAP Ariba.

The following topics are covered in that Introduction to SAP Ariba course:

- History and necessity of Ariba in the global digital ecosystem,

- Plan – Buy – Pay process detailed explanation,

- Ariba Spend Visibility functionality and reporting possibilities,

- Ariba sourcing of suppliers within the global business network,

- Ariba contract management and implications on legal resources.

What are your needs for SAP Ariba global business network usage? Feel free to let us know which topics you would like to see covered in our future courses.

by Yoann Bierling

More Blogs by Yoann Bierling

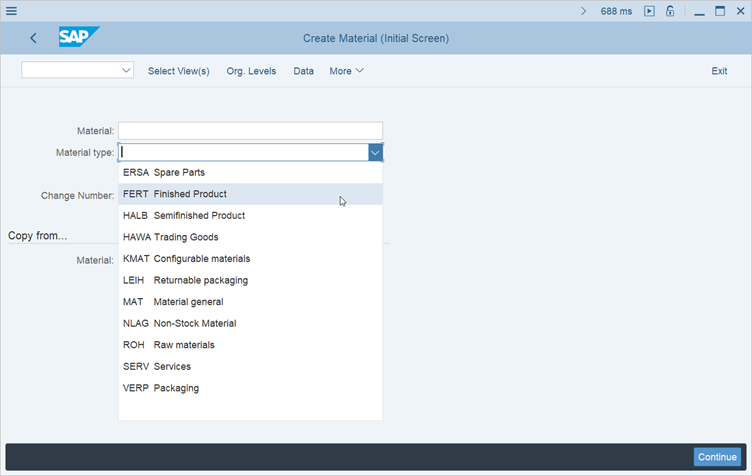

All You Need to Know About Material Types in SAP...

There are various basic material types available by default in any sta...

Four Steps to Effective SAP Data Cleansing

It's an inevitable problem. Over time, data gets messy. This inclu...

The 8 Basic Functionalities of SAP Ariba

Acquired by SAP in 2012 for $4.3 billion, the SAP Ariba netw...

Related Blogs

How does Operational Procurement work?

The operational procurement process is what allows a professional orga...

Are All of Your Customers Profitable to You?

Are All of Your Customers Profitable to You? The only value a compa...

What's Broken about Budgeting?

How many people in your organization love the annual budgeting process?...

.png)