How does Operational Procurement work?

by Yoann Bierling

The operational procurement process is what allows a professional organization to perform purchases, that will be useful either for office purposes, for production, or for SAP sales and distribution.

The operational procurement process is what allows a professional organization to perform purchases, that will be useful either for office purposes, for production, or for SAP sales and distribution.

The larger the company, the more it will benefit from applying best practices around purchasing – however, even the smaller business will gain from using these processes, especially by leveraging the best practices at first, and eventually by joining suppliers’ network like SAP Ariba.

That is because different offices might need the exact same office supplies, and two different plants, even in different countries, might require the exact same raw material for their production processes, or a new project might require the same consulting services.

In all these cases, applying the SAP Operational Procurement best practices within the purchasing department will allow savings for the company on several dimensions:

- Financial, as some larger contracts might be negotiated with suppliers for goods or services used in different company location,

- Temporal, as the procurement process won’t have to be started from scratch repeatedly, and the history is accessible and shared within the organization,

- Human, as the SAP best practices will allow the whole operation procurement flow to be smoother,

- Report, with the ability to extract, share, and report on many KPIs related to the whole procurement process for internal purchasing organizations

Figure 1: Operational Procurement process

Demand Determination

The Operational Procurement process starts with demand determination. What is needed, which services or materials are necessary for myself or my colleagues to perform our jobs, such as produce the right quantity to fulfil a customer order.

When the needs have been detailed, it is time to determine the sources. Who is possibly able to deliver these products to the locations in which they will be used.

The demand determination in the operational procurement process goes through the creation of Purchase Requisition, a document in SAP that centralizes all the materials purchase requisitions within the company.

The transaction for the Purchase Requisitions creation within SAP Purchasing is ME51N.

Figure 2: Purchase Requisition transaction in SAP

Supplier Selection

Afterwards, select which supplier from these sources will be the right one for the current purchase in time, quantity and quality.

Within SAP, we will start by creating Requests For Quotations (also called RFQ) in transaction ME47. An RFQ is used to ask suppliers to provide their terms for a specific order.

An RFQ will be sent to every possible provider that has been identified, asking them in a timely manner to let the company know if and how they will be able to deliver the requested goods or services.

Figure 3: Request For Quotation document

The suppliers that can fulfil that demand will answer with a quote, listing their exact terms and conditions for that order delivery. These answers are the first binding documents of the Operational Procurement process. If the quotation is accepted, and the terms are not respected, it would be a breach of contract and might lead to

legal actions.

Figure 4: Quotation received from a supplier in answer to an RFQ

These answers, the quotations, will be recorded in transaction ME48, eventually in reference to an existing Request For Quotation, and are part of the SAP quotation process.

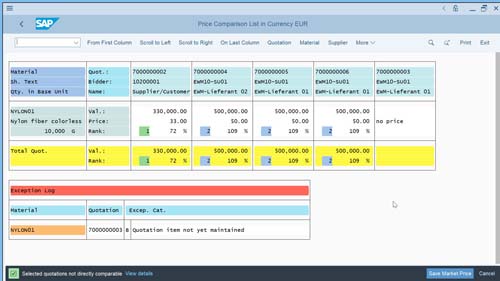

Quotations received will be compared by the purchasing department, and the best offer will be selected: the cheapest, with the best quality, that promises to fulfil the order in time.

This process is called price comparison and is performed in transaction ME49. SAP helps there to easily compare these quotations between each other, and make a smart purchasing decision based on facts, by displaying the quotations in a way that allows to find the best provider for the requested delivery.

Figure 5: Price comparison of quotations

Order Monitoring

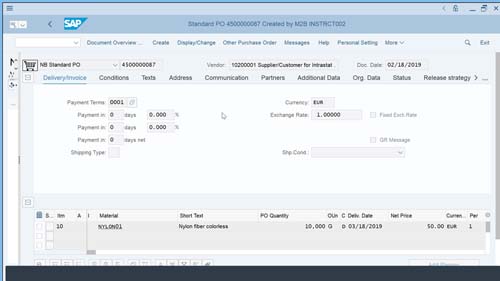

Once the provider has been identified, it is time to process purchase orders, in other words to create the binding order documents to send to the suppliers, asking them to deliver some goods or services as per agreed conditions.

An order is sent to a provider by the purchasing department via the creation of a Purchase Order (also called PO), a legally binding document, in transaction ME22N.

Figure 6: Purchase order creation

While waiting for the orders to be delivered, orders are monitored. Are the stocks going to be available on time, can previous production steps be started, are next steps planned to be finished on time.

When the goods are received, they are registered and checked against corresponding orders, to make sure that they have been correctly fulfilled. The goods receipt process will be handled by the warehousing team.

At this stage, surprises might be detected: broken products, missing goods, wrong sizes, low quality, … Any of these problems might lead to additional documents creation, to either trigger a return, negotiate a credit with the supplier, or trigger legal actions in extreme cases.

Invoice Process

The invoice can then be verified, and eventually reviewed in case of delivery issue and possible returns.

Payment can be processed afterwards to close this round of orders; invoice is the final document in the procurement process.

The vendor invoice management is the last step of the SAP operational procurement process, and will generally be handled by a specific team, closer to the accounting department, that will handle the monetary payment to the provider.

After the invoice has been settled, the purchasing process is complete, allowing to produce finished goods and start toll manufacturing processes, or resale to take place.

SAP Operational Procurement Course

Learn more about implementing Operational Procurement processes in SAP from the purchasing point of view and their use in the purchasing processes by following our online course on Operational Procurement in SAP.

The following topics are covered in that course:

- Self Service Requisitioning and creation of Purchase Requisition,

- Requirements Processing through Request For Quotation, Quotation, and Price comparison,

- Purchase Order Processing, Service Purchasing, and Purchase Order creation,

- Purchase Order Collaboration and the integration with the Ariba network,

- Procurement Analytics and corresponding FIORI apps.

What are your needs for SAP Operational Procurements? Feel free to let us know which procurement topics you would like to see covered in our future courses.

by Yoann Bierling

More Blogs by Yoann Bierling

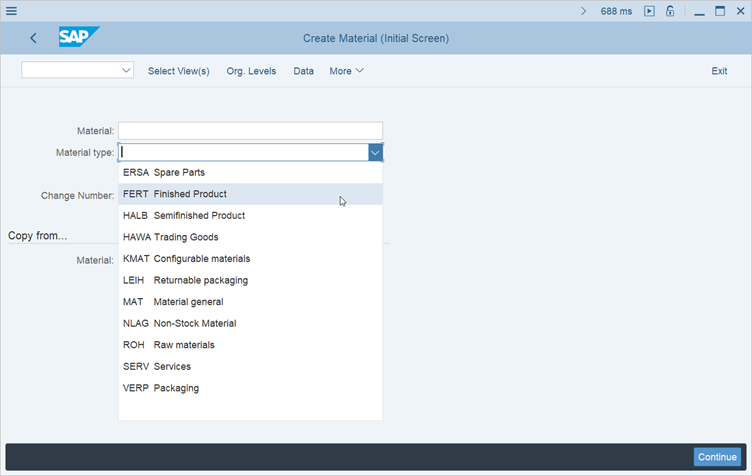

All You Need to Know About Material Types in SAP...

There are various basic material types available by default in any sta...

Four Steps to Effective SAP Data Cleansing

It's an inevitable problem. Over time, data gets messy. This inclu...

The 8 Basic Functionalities of SAP Ariba

Acquired by SAP in 2012 for $4.3 billion, the SAP Ariba netw...

Related Blogs

Are All of Your Customers Profitable to You?

Are All of Your Customers Profitable to You? The only value a compa...

What is the Plan-Buy-Pay Process?

What is the Plan-Buy-Pay Process? The Plan-Buy-Pay process, which is the...

.png)